Industrial Buildings

Saliba Construction Co., Inc. has been constructing industrial facilities for the past sixteen years. Our major clients include Purdue Farms, General Electric Corporation, and Lockheed-Martin.

Saliba Construction Co., Inc. has been constructing industrial facilities for the past sixteen years. Our major clients include Purdue Farms, General Electric Corporation, and Lockheed-Martin.

Purdue Farms involved constructing a three phase addition to their chicken processing plant while maintaining daily operations. The project has to be coordinated with much of the work done during off hours for the plant. Precast industrial construction was utilized to fast track the construction. The precast was erected and the facility's conveyors installed without any lost production time to the client.

The Company was hired for a design-build industrial project at the General Electric plant in Dothan, AL where GE manufactures smaller DC current motors. We were charged with putting together a design team to work with two of GE's industrial engineers to move all equipment operations from their Eerie, Pennsylvania plant to Dothan. We had to design and coordinate not only the building and mechanical systems, but we had to travel to Eerie and measure and coordinate all space and rail requirements for their floor mounted jib cranes and overhead rail cranes. All electrical loads and design had to match up with the relocated equipment and be ready for immediate connection once moved. We were ultimately responsible for all rigging of the relocated equipment when it arrived to the newly constructed facility. Numerous changes were initiated by the owner as they integrated some new equipment, but the original schedule was maintained and the original GMP was not exceeded.

The Company was hired for a design-build industrial project at the General Electric plant in Dothan, AL where GE manufactures smaller DC current motors. We were charged with putting together a design team to work with two of GE's industrial engineers to move all equipment operations from their Eerie, Pennsylvania plant to Dothan. We had to design and coordinate not only the building and mechanical systems, but we had to travel to Eerie and measure and coordinate all space and rail requirements for their floor mounted jib cranes and overhead rail cranes. All electrical loads and design had to match up with the relocated equipment and be ready for immediate connection once moved. We were ultimately responsible for all rigging of the relocated equipment when it arrived to the newly constructed facility. Numerous changes were initiated by the owner as they integrated some new equipment, but the original schedule was maintained and the original GMP was not exceeded.

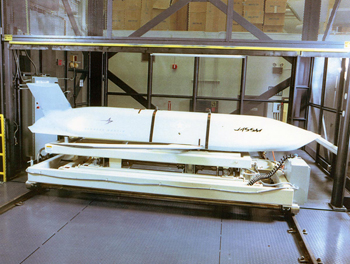

The Company served as a combination general contractor and construction manager for over a ten year span for Martin-Marietta Missile Control, and later Lockheed-Martin Missile Control. The client moved their government contracted missile industrial manufacturing facilities from Orlando to Pike County, Alabama. We managed the construction for their Hellfire missile, Javelin Missile, Patriot Missile, and later retrofit of the Patriot facility for the Jassm Missile. All construction consisted of super flat slabs which were bead blasted and coated for the finish product, tilt-up exterior wall system, and cast-in-place walls and roof for the test/blast cells. The Jassm upgrade of the Patriot facility required one of a kind design for the anechoic chamber, the p-flow system, the paint booth, and the lift/conveying system for the missile to enter the test chamber. These were all unique designs which have never been duplicated, and have worked failsafe since they were installed.

The Company served as a combination general contractor and construction manager for over a ten year span for Martin-Marietta Missile Control, and later Lockheed-Martin Missile Control. The client moved their government contracted missile industrial manufacturing facilities from Orlando to Pike County, Alabama. We managed the construction for their Hellfire missile, Javelin Missile, Patriot Missile, and later retrofit of the Patriot facility for the Jassm Missile. All construction consisted of super flat slabs which were bead blasted and coated for the finish product, tilt-up exterior wall system, and cast-in-place walls and roof for the test/blast cells. The Jassm upgrade of the Patriot facility required one of a kind design for the anechoic chamber, the p-flow system, the paint booth, and the lift/conveying system for the missile to enter the test chamber. These were all unique designs which have never been duplicated, and have worked failsafe since they were installed.

No matter what your industrial design and/or building needs, Saliba has the know how to make your project a cost effective on time reality.